Plastic Injection Molding Company for POS Display

We offer an all-inclusive customization service to clients who want customized molds of plastic shelves for injection molding operations. We manufacture custom plastic POS display molds which are precise for clients’ specifications, enabling the production of excellent custom plastic shelves.

Custom POP Displays Mould by Experts

Custom POP display molds require expertise for the creation of unique products. Works with experts that manufacture molds to your detailed specifications. Our services stand out as we guarantee products that conform to all recognized national and global standards.

Custom services offered include:

- Supermarket Display Shelf Mold

- Cosmetics Display Shelf Mold

- Makeup Display Shelf Mold

- Product Display Shelf Mold

- Pharmacy Storage Racks Mold

- Plastic Digital Signage Mold

Previous Injection Molded Plastic POS Display Projects

We design, manufacture, and supply molds to an expanding client base worldwide. With an annual production of 900-1000 molds, including carte molds, baby product molds, plastic bucket molds, automobile molds, and home appliance molds, we deliver various kinds of molds to many industries.

In addition, while we major provide injection molding services, we also offer other services like insert molding and overmolding, enabling us to produce and supply cost-effective bulk plastic products.

Benefits of Injection Molded POP Displays

High-Quality Products

All our materials are sourced from reliable suppliers. Materials from suppliers undergo strict quality checks to ensure they conform to our quality standards. We only use top-quality steel in making plastic POP display molds and qualified resins for custom POP displays.

Injection Molding Experts

Team of experts is backed by several years of experience in the manufacturing industry. Our experts possess the know-how required to offer premium injection molding services. Working with us, you have direct access to them as they oversee your project.

Custom Solution

Our comprehensive solution to customization makes us the best option for injection molding services. We manufacture various molds, including plastic POP display molds that precisely meet all your specifications. By working with an OEM expert, you’re guaranteed the best custom service.

Other Injection Molded POP Displays

Custom POP Display

We engage in proper analysis of the details of your custom project. We achieve a perfect product design for your custom POP display by integrating Design For Manufacturability (DFM) in our process, which increases speed, simplifies the process, and reduces cost.

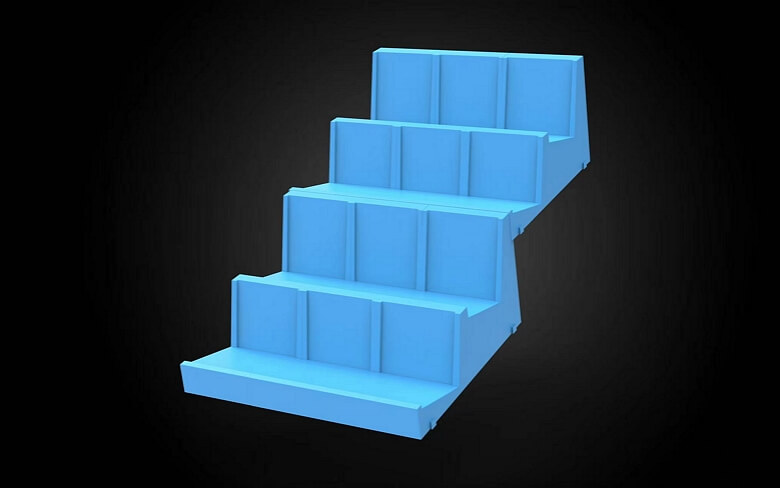

Plastic Shelves Mold Design

Blessed with the best workers who provide suitable design solutions. In offering mold design services, our professional workers incorporate your product design and quality requirements. All those things ensure that your plastic shelf molds are well-designed and can produce functional parts.

3D Printing

We provide 3D printing services for creating prototypes of your plastic shelves product design. Our state-of-the-art 3D printing machines create prototypes of different specifications. This enables a quick turnaround time on complex designs.

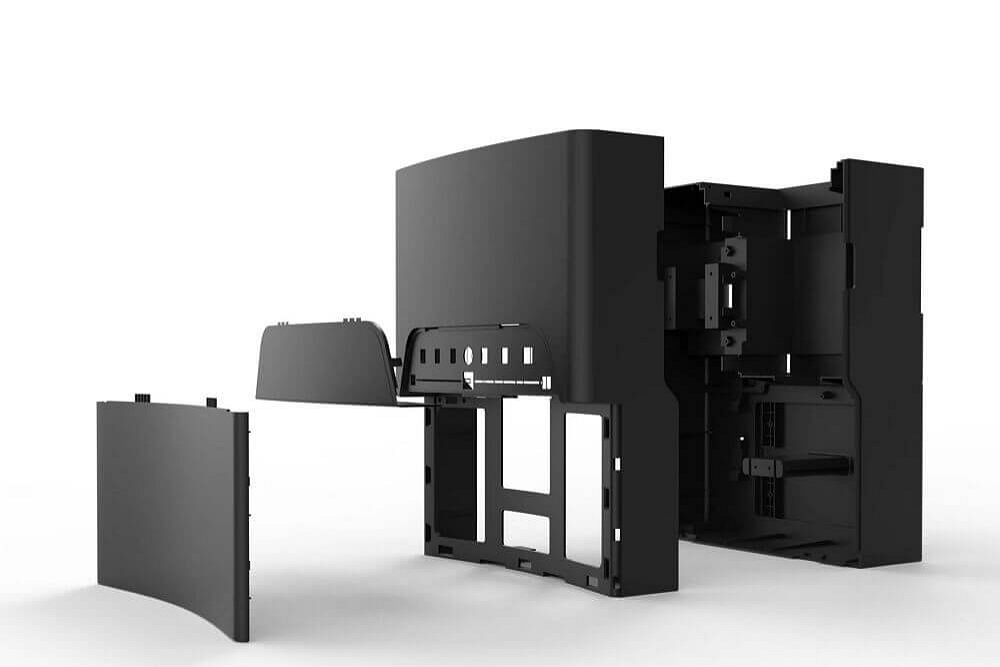

CNC Machining

It involves the use of computerized controls to produce your custom digital signages. Using the CNC drilling, milling, and turning machines, prototypes of complex designs and large products are easily and quickly created, resulting in a fast turnaround time.

Injection Mould Making

Working with us allows you access our wealth of experience in creating quality molds. We create plastic shelf molds that accurately produce your custom product. Implementing technology and advanced software in our world-class factory, we create your custom products to be efficient and superior.

Produce Plastic Shelves

We use our molding techniques to produce plastic shelves that meet your requirements. From raw materials to finished products, we incorporate quality in creating your bulk custom plastic shelves. While your products are designed to have appealing appearance, we also guarantee optimal performance.

Insert Molding

This involves the inserting of a metal part into a mold before proper injection molding occurs. This molding can be done in several ways to fit your requirement.

Overmolding

This process involves the creation of a seamless component by combining several materials. In this process, the second shot of molding resin is injected to cover the first layer.