- Home

- Equipment

For many decades, Marcon has been providing quality products to our customers at a competitive price while maintaining a superior level of service. The success of these attributes is in part due to partnering with state-of-the-art equipment manufacturers which allows our manufacturing team to process our products at higher quality levels and efficiency rates.

Our injection molding equipment portfolio ranges in tonnage from 100 to 660 US Tons. Each molding machine is equipped with high-speed robotic takeout which allows us to manufacture at reduced cycle times with less risk of manufacturing interruptions due to the ongoing challenges of labor constraints.

Partnering with OEMs like Husky, Bekum, Brown Machinery Equipment, Wittmann, etc., allows us to manufacture with less risk of downtime due to the superior support, service, and spare part stocking plans that each of our partners provide.

Specific types of equipment that we may use for plastic injection molding services include:

-

Injection molding presses: These are the machines that perform the actual injection molding process. They come in a range of sizes and can be configured for different purposes, such as producing small precision parts or large automotive components.

-

Robotics: Many injection molding operations use robots to handle the injected parts as they come out of the mold and move them to a designated area for further processing or packaging.

-

Temperature control equipment: Plastic resin must be heated to a specific temperature in order to be properly injected into the mold. This is typically done using specialized heating equipment such as barrel heaters or heat exchangers.

-

Material handling equipment: Injection molding operations often involve handling large quantities of plastic resin and other materials. This can be done using a variety of equipment such as hoppers, feeders, and conveyors.

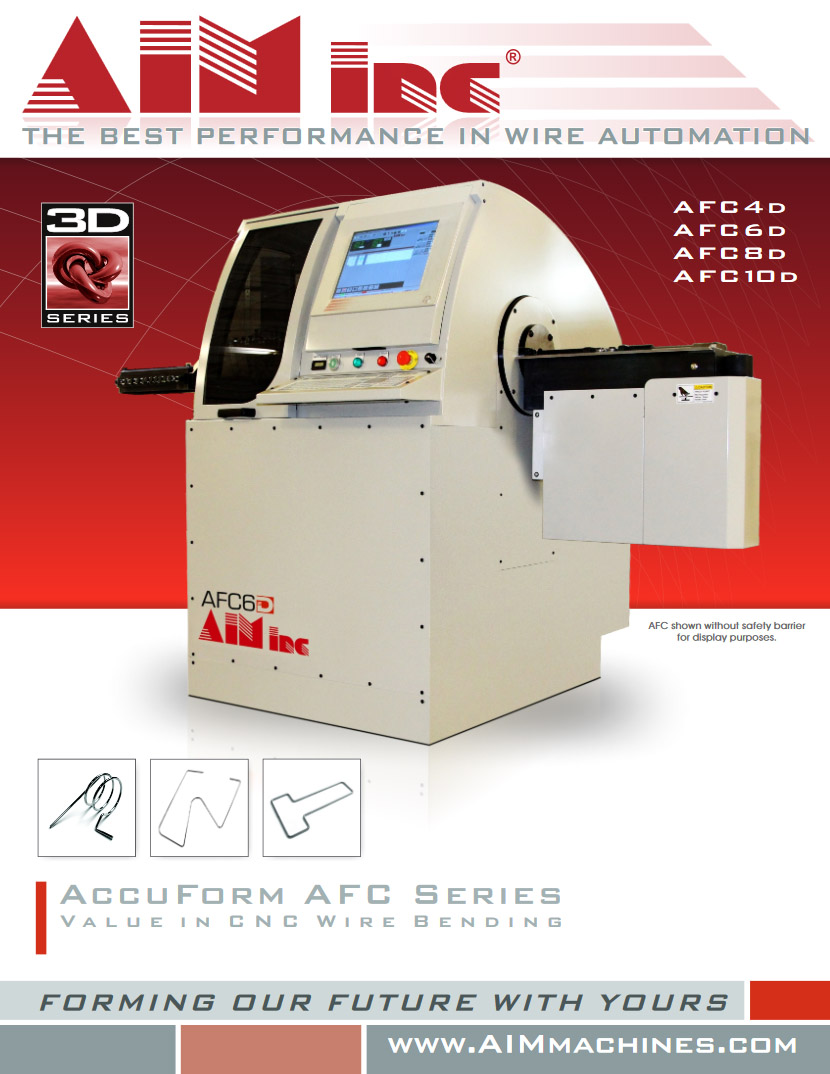

As for Marcon's display solutions services, Marcon Solutions may use a range of equipment and technology to design and manufacture display products for their clients. This could include CAD software for design, CNC machinery for cutting and shaping materials, and specialized printing equipment for producing graphics and other decorative elements.

Quick Navigation

About Equipment Our Services Portfolios Products Plastics and Pop Display Solutions News Contact©2023 MarCon, Inc.® | ALL RIGHTS RESERVED | Industrial Website Catalog by WYSIWYG Marketing